Dental burs are essential rotary instruments used in dentistry for cutting, grinding, or polishing hard tissues such as teeth, enamel, or bone. They serve as the “drill bits” for dental handpieces, enabling precise and efficient procedures in various dental applications. Dental burs are characterized by their sharp-edged blades and multiple cutting edges, which are designed to remove material effectively while minimizing damage to surrounding tissues.

These instruments are widely used in general dentistry, orthodontics, and prosthodontics for procedures such as cavity preparation, crown work, and tooth shaping. Their versatility allows them to be applied in both routine and specialized dental treatments, including interproximal reduction (IPR), gingivectomy, and the removal of old restorations. The design of dental burs varies significantly, with differences in shape, size, and material catering to specific clinical needs.

Dental burs are typically made from high-quality materials such as tungsten carbide or diamond-coated surfaces. Tungsten carbide burs are known for their durability and resistance to wear, making them ideal for cutting through hard materials like metal or ceramic. Diamond burs, on the other hand, are coated with layers of diamond particles, providing exceptional cutting efficiency and precision, especially for enamel and bone.

The ISO (International Organization for Standardization) classification system further categorizes dental burs based on their shape, size, and intended use. For example, ball burs are commonly used for opening cavities or creating retention areas, while torpedo-shaped burs are specialized for cavity preparation. Inverted cone burs are versatile tools often employed for creating undercuts or shaping occlusal surfaces.

In modern dentistry, the selection of the appropriate dental bur is critical for achieving optimal results. With advancements in material science and manufacturing techniques, dental burs have become more efficient and long-lasting, reducing the need for frequent replacements. Their role in enhancing the precision and outcomes of dental procedures underscores their importance in contemporary dental practice.

Overall, dental burs are indispensable tools in the dentist’s arsenal, offering a balance of performance, durability, and adaptability to meet the diverse demands of dental care. Their continued evolution ensures they remain a cornerstone of modern dental treatments, contributing to better patient outcomes and streamlined clinical workflows.

Classification of Dental Burs

Dental burs are classified based on their shape, size, material, and intended use. This classification helps dental professionals select the appropriate bur for specific procedures, ensuring precision and efficiency in various dental applications. Below is a detailed overview of the primary classification categories of dental burs.

Classification by Shape

The shape of a dental bur is one of the most critical factors in determining its use. Different shapes are designed to perform specific tasks, ranging from cavity preparation to intricate shaping of dental structures. Common shapes include:

- Ball Burs: These burs are spherical in shape and are commonly used for opening cavities or creating retention areas in dental procedures. They are also useful for preparing grooves for prosthetics and are often the first choice for initial cavity preparation due to their versatility.

- Torpedo Burs: Named for their resemblance to a torpedo, these burs are specifically designed for cavity preparation. Their elongated shape allows for precise removal of decayed material while minimizing damage to surrounding tooth structure.

- Inverted Cone Burs: These burs feature a cone-shaped head that is inverted, making them ideal for creating undercuts in dental restorations. They are also used to form occlusal surfaces and are highly versatile in various dental surgeries.

- Cylindrical Burs: Cylindrical burs are straight and are often used for shaping and polishing surfaces. They are particularly useful in procedures involving composite materials and amalgam restorations.

- Needle Burs: These burs are thin and pointed, designed for detailed work in tight spaces. They are often used for interproximal reduction (IPR) and other precision tasks.

Classification by Size

Dental burs also vary in size, which is crucial for accessing different areas of the mouth and performing specific procedures. The size of a bur is typically indicated by a number, with smaller numbers corresponding to larger burs and larger numbers indicating smaller burs. For example:

- Large Burs (e.g., #4 to #6): These are used for removing large amounts of material quickly and are often employed in the initial stages of cavity preparation.

- Medium Burs (e.g., #8 to #10): These burs are versatile and are used for both removing material and refining the shape of the cavity.

- Small Burs (e.g., #12 to #14): These are used for fine detailing and are essential for precision work in areas that are difficult to access.

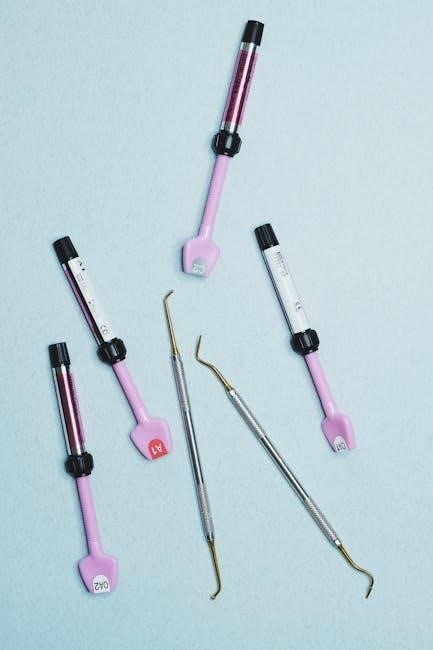

Classification by Material

The material of a dental bur significantly impacts its performance and longevity. Two of the most common materials used are tungsten carbide and diamond-coated burs.

- Tungsten Carbide Burs: These burs are made from tungsten carbide, a durable and wear-resistant material. They are ideal for cutting through hard materials such as metal and ceramic and are often used in procedures involving crown preparation and skeletal or acrylic partial dentures. Tungsten carbide burs are also known for their high precision and are classified according to ISO standards, with the ISO 500 numbering system being a common reference.

- Diamond Burs: Diamond burs are coated with multiple layers of diamond particles, which provide exceptional cutting efficiency. They are particularly effective for cutting through enamel and bone and are widely used in procedures such as tooth preparation and orthodontic adjustments. Diamond burs are thicker than carbide burs, which makes them more durable and long-lasting. They are also classified based on their grit size, with finer grits being used for polishing and coarser grits for heavy cutting.

Classification by Use

Dental burs can also be classified based on their specific applications in dental procedures. This classification helps in selecting the most appropriate bur for a particular task, ensuring optimal results.

- Preparation Burs: These burs are used for removing decayed material and shaping the tooth structure. They are available in various shapes and sizes to accommodate different types of cavities and restorations.

- Finishing Burs: Finishing burs are used to smooth and polish the surfaces of restorations. They are available in different materials, such as white stone for composite materials and green stone for amalgam.

- Specialty Burs: These burs are designed for specific procedures, such as interproximal reduction (IPR), crown cutting, and gingivectomy. Specialty burs are tailored to meet the unique demands of these specialized applications.

ISO Classification

The International Organization for Standardization (ISO) has established a classification system for dental burs, which helps in standardizing their shapes, sizes, and uses. The ISO classification is based on a numbering system that provides a clear reference for selecting the appropriate bur for a specific procedure. For example:

- T Series: These burs are used for full crown preparation and are characterized by their sharp edges and precise cutting capabilities.

- TF Series: These burs are designed for preparing the shoulder of metal-porcelain teeth and feature a right angle at the top for precise shaping.

- TC Series: These burs have a sharp top and are used for creating undercuts and forming occlusal surfaces.

Shank Types

Dental burs also differ in their shank design, which affects how they are held and used in dental handpieces. The shank is the part of the bur that is attached to the handpiece, and its design can influence the bur’s stability and maneuverability. Common shank types include:

- Friction Grip